Short Description:

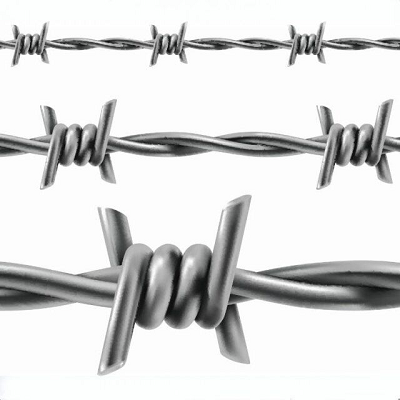

Barbed wire:

Barbed wire can be made from various materials, including copper, galvanized steel, aluminum and galvanized iron. The main use of barbed wire is in fencing, particularly for private residences, businesses and public property. Barbed wire is an conductive metal wire that has been bent into varying shapes. Barbed wire may have one or numerous metal strips in between its bendable metal barbs that provide gripping traction.

Galvanized steel barbed wire

Galvanized steel barbed wire is a kind of galvanized steel wire designed with sharpened ends arranged in short runs along the wire strand(s) or strands. It’s primarily used to build lightweight fences, decking, and even is sometimes used to strengthen walls surrounding secured land. This type of wire has galvanized steel bars that are galvanized at one side or both sides. The most common uses are building fences, securing and enclosing patios, retaining walls, fencing, and light poles among other things.

There are two types of barbed wire which are low pressure and high tension. Low tension wire has a higher stress level than high tension. High tension wire is known for its high tensile strength. When using high tension wire to build a fence, you’ll generally be using galvanized steel barb wire, which is the more commonly used kind of wire. Galvanized steel barb wire comes in two different forms – drawn and unlapped. A drawn wire has all the ends cut parallel and an unrolled strand of this wire is drawn over the top of a drawn strand to form a complete loop.

In order to make a loop with galvanized steel barbed wire, you need to have a large cross sectional area, a sharp hook on the end of the barbed wire, and a bending iron. The loop can be bent to various shapes depending on what you need it for. Once the loop is formed, the bend is filed to help the metal stick together better. Each loop then needs to be reinforced with galvanized steel wire after it is formed. This entire process requires patience and workmanship.

Barbed Wire Specification:

Single barbed wire

| Wire gauge(mm) | Barbed spacing(inch) |

| 1.8×1.8 | 1.96-5.9″ |

| 2.0×2.0 | |

| 2.2×2.0 | |

| 2.2×2.2 | |

| 2.5×2.2 | |

| 2.6×2.2 | |

| 2.7×2.2 | |

| 2.8×2.2 |

Double twisted barbed wire

| Wire gauge (mm) | Barbed spacing (inch) |

| 1.4×1.4 | 4″-5″ |

| 1.5×1.5 | |

| 1.6×1.6 | |

| 1.7×1.7 | |

| 1.8×1.8 | |

| 1.9×1.9 | |

| 2.0×2.0 |

PE/PVC Coated barbed wire, stoving varnish barbed wire

| PVC/PE coated barbed wire, | Before coating | After coating | Barbed distance(cm) | Barbed length(cm) | Tensile strength(kg) |

| 1.0-3.5mm | 1.4-4.0mm | 7.5-15 | 1.5-3 | 40-50 | |

| BWG11#-20# | BWG8-17# | ||||

| BWG11#-20# | BWG8-17# | ||||

| PVC/PE coating thickness: 0.4-0.6mm,different color or length are available at customers’ request | |||||

Barbed Wire Packing Detail:

(1) Steel wire roller with steel wire handle.

(2) Steel wire roller with plastic handle.

(3) Steel wire roller with wooden handle.

(4) Wooden roller with rope handle.

Woven bag, by pallet, and as your request.